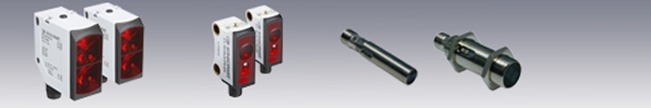

The photoelectric proximity switches combine transmitter and receiver in one housing. The light emitted by the transmitter is reflected by the target object. The receiver evaluates this reflected light.

The retro-reflective light barrier combines transmitter and receiver in one housing. The light emitted by the transmitter is reflected by a reflector. The receiver evaluates the reflected light. The small size of the reflector is advantageous. In addition, it is easy to install being a passive element, thus not requiring connection.�

Transmitter and receiver of through-beam sensors are separate. This means that the emitted light has to travel the distance between transmitter and receiver only once. Therefore they are called through-beam sensors. These types can reach very large scanning ranges.

The FL 20 – the David amongst the Goliaths: It covers all the requirements of optical sensor technology in small spaces, offering high precision detection with ease of use.

The FL 70 R-..D is the high-end sensor for fibre optics with a 4 digit display. It is characterized by simple settings and many additional functions, e.g. fine adjustment of the switch point, inversion of the switch output, adjustment of accuracy and speed, window programming, time functions and tamperproof protection. The display is always clearly visible thanks to a 180° rotatable screen.

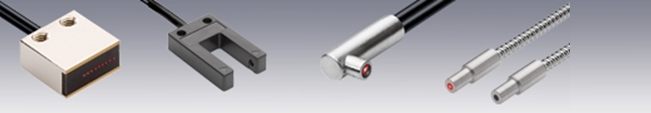

Fibre optics are basically divided into two categories – glass and plastic transmission media. SensoPart offers its products in both versions. Fibre optics with glass are referred to as glass fibres. Use of a very high-quality mineral glass achieves much better performance data compared with plastic fibres.

- Slot Sensors and Optical Fibres

The main feature of our fork sensors is their reliability with utmost accuracy. Even very small objects are reliably detected. High switching frequencies enable the detection of moving objects. All versions have a plug connection and use visible red light.

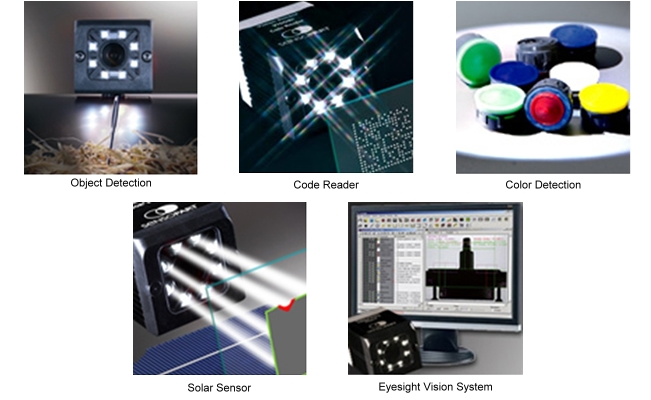

Fast and accurate measurement, precise positioning and detection of a wide range of materials – distance measurement is a central requirement in many areas of automation technology. Our optical sensors use the triangulation method for working ranges under 1 m, time-of-flight measurement is used for greater operating distances.

- Color, Contrast and Luminescence Sensors

If products are to be automatically detected or sorted in an industrial process, object colors or colored markings can be detected using SensoPart contrast or color sensors.

Inductive proximity sensors are indispensable in industry today. They use an alternating magnetic field produced by an oscillator as their measuring medium. If a metallic object enters this magnetic field, the oscillation amplitude changes. This is analyzed electrically. In contrast to optical or ultrasonic sensors, they are however only for use in close-up range. Typical operating distances vary between 0.5 mm and 40 mm.

Our capacitive sensors detect the disturbance in an electric field caused by the presence of an object. This disturbance can be generated both by conductive (metal) and non-conductive (isolators) objects. Typical applications are in the pharmaceutical and food industry or in the paper and wood processing/machining sector.

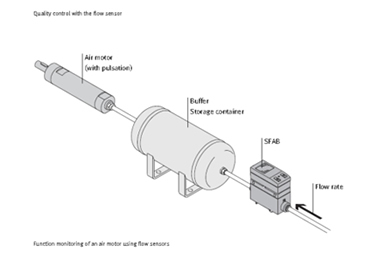

Ultrasonic sensors use a short high frequency acoustic pulse as measuring medium. This is emitted towards e.g. an object which reflects it back towards the sensor as an echo. The time of flight can be used to determine e.g. distance. Ultrasonic sensors are often used in applications where the physical principle of optical sensors reaches its limits, i.e. the detection of transparent objects or liquids. Another typical application is level measurement e.g. of bulk goods from a long distance.